FDC stands for “Fire Department Connection,” which is a frequently overlooked, yet vital component in maintaining the safety of your building and all that lies within it. Below, we’ll take a look at everything you need to know about FDCs, as well as how they relate to your fire suppression system and the safety of your building.

What Is an FDC, and What Does It Do?

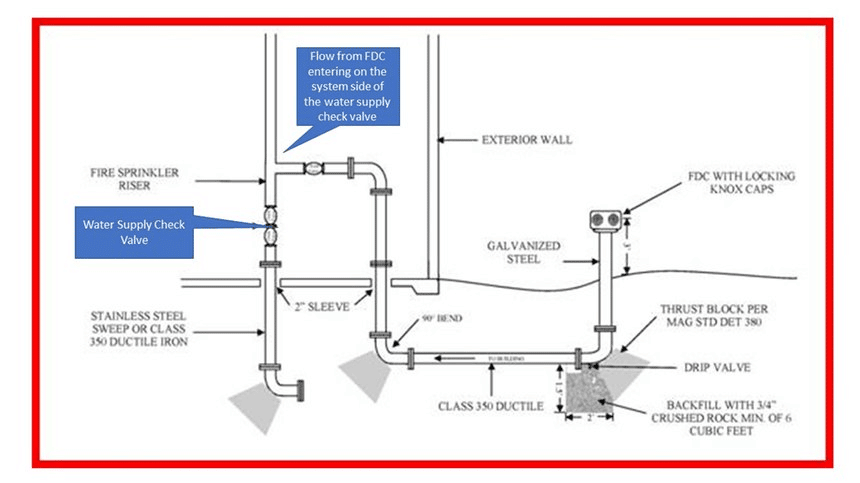

An FDC is a connection through which a fire department can pump water into the sprinkler system, standpipe, or other system within a building. This provides additional water to supplement the building’s existing water supplies, which is a huge aid in the fire extinguishing process.

If your building were to catch fire, your local fire department can simply connect their pumper truck’s hose line to your FDC, then add water to ensure your building constantly has sufficient water at a sufficient pressure to completely suppress the fire. Pumping water into the FDC not only helps maintain water supply, but also acts as a backup in case any of the follow situations occur:

- A valve is closed between between the domestic water supply and the sprinkler system, which prevents necessary water from reaching the system

- Your building’s occupancy has changed since the fire sprinkler system was installed, meaning there’s now more risk than it was originally designed to handle

Without an FDC, the effectiveness of your fire suppression system is drastically reduced. In fact, the installation of an FDC can be the difference between a successfully suppressed fire and the complete loss of your facility. That’s why an FDC is required for commercial buildings and for all fire sprinkler systems and standpipe systems, per NFPA 13 and NFPA 14.

Where Is an FDC Located?

In most cases, FDCs are located on your facility’s exterior. However, there are some instances where they’re placed apart from the building.

No matter where it’s located, your FDC must be clearly marked by a sign that describes if it supplies a fire sprinkler or standpipe system. It should also state how much pressure the FDC requires, and whether it supplies the entire facility, or only a portion of it.

FDC Components

Most FDCs have pipes that stick out from the exterior of a building, usually in a Y shape. This is usually called the inlet valve, and it has two female fittings that are each 2.5” in diameter.

The inlet valve then connects to an outlet pipe that is around 5” in diameter and runs behind the building’s wall. It’s where the FDC connects with your existing sprinkler system riser.

Finally, the FDC has a check valve and plugs. The check valve stops any water backflow, and the plugs cover the inlet valves to prevent foreign materials from clogging the pipes — both ensuring that the FDC and connected systems are working as effectively as possible.

FDC Inspections and Service Requirements

As you may infer, the NFPA requires that your FDC be inspected, tested, and maintained regularly. These requirements differ based on which type of fire suppression system is installed in your facility.

Inspection requirements for FDCs connected to a sprinkler system:

- Isolate and hydrostatic test for 2 hours at 150 psi (10 bar)

- Main drain test

Inspection requirements for FDCs connected to anything other than a sprinkler system:

- Isolate and hydrostatic test for 2 hours at 50 psi (3.5 bar) above the normal working pressure (200 psi/14 bar minimum)

- Main drain test

Service requirements for all FDCs:

- Inspect for leaks at system pressure

- Main drain test

For more information and answers to other frequently-asked fire suppression system questions, be sure to head over to the rest of the Vanguard blog! And if you have any specific questions, or it’s time for your regular service or system inspection, our team is here to help. Schedule your appointment today!